Multimodal Samples with Laser Diffraction

Laser diffraction measures scattering intensity from particles in suspension as a function of scattering angle, light wavelength and light polarization. Then it uses a mathematical means to obtain particle size distribution from the raw intensity data. The size range, sensitivity and resolution of the instrument rely on its hardware design, assembly quality and software algorithm. Of course, to obtain a good result, correct operation and sample preparation are also very important. In the process the data analysis algorithm plays a vital role in obtaining high resolution and accurate particle size distribution result from the raw data. To demonstrate the capability of a laser diffraction instrument, people often use a mixture of well characterized spheres of narrow distribution because for these samples operator error and environmental influence are often minimal. Such a sample is often called a multimodal sample. However, most real industrial or research samples don’t even come close to these narrow distributions. They typically have either a narrow single peak or a broad peak with one or more modals. In addition, distribution and modality of samples are often unknown. Therefore, a good algorithm shall not presume any distribution or modality of the sample and still be able to obtain accurate results with high resolution. When an algorithm cannot be applied to a broad range of samples with the goal of obtaining good and accurate results, adding some constraints may help the math process and improve the result. A typical constraint is to input the allowed modality and distribution width for each peak so the output will be the one satisfying the constraint. If the sample meets the requirements of the constraint as the ones used in the algorithm, a better result may (or may not) be obtained. Otherwise, either a nonrealistic or biased result will be produced.

Examples of Different Fitting Modes

Let's take a look at an example with the use and without the use of such a constraint. A laser diffraction instrument provides three options for the analysis mode selection:

- A: Single Mode – This is a special analysis routine for monomodal characterization lattices.

- B: Multiple Narrow – This is an extension of the Single Mode routine which is optimized to resolve two or more extremely narrow fractions produced by mixing two or more monodisperse materials.

- C: General Purpose - The recommended analysis mode to always use unless characterization lattices are being measured.

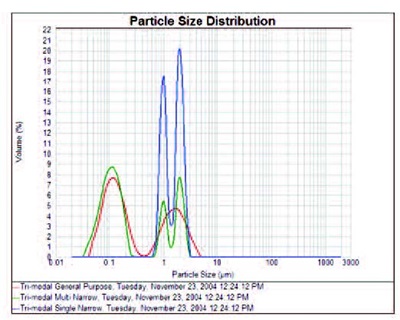

The sample used is composed of a trimodal mixture of polystyrene microspheres with particle size of 0.15 μm, 1.0 μm and 2.0 μm from a reputable vendor. The above three modes were chosen to analyze the same set of data from the sample. Completely different results were then obtained (figure 1).

It is obvious from the figures that, in order to obtain a particle size distribution certain information about the material needs to be known. Otherwise, to determine which result is correct will be a tough job for a technician. In this case if one chose the mode other than the Multi Narrow, a low resolution result will be obtained. But then for an unknown sample, other analyses must be done to determine sample modality before the sample can be analyzed using this instrument.

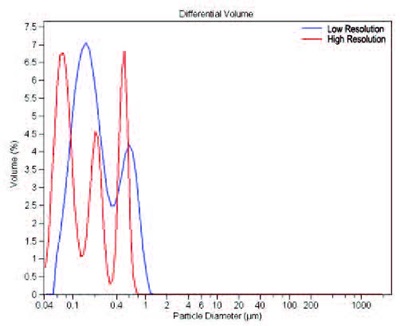

But if the hardware lacks the capability to measure particles at a certain range or the algorithm was not well designed and tuned, even with the correct constraint, incorrect or low resolution results still would be produced. For example, when another submicron trimodal sample from the same vendor (modal sizes 81 nm, 200 nm, and 500 nm) was used and the Multi Narrow mode was chosen to analyze the sample, only a low resolution bimodal result was obtained (figure 2, low resolution).

Another instrument from a different manufacturer who uses a patented Polarization Intensity Differential Scattering technology (PIDS) is able to achieve high resolution. This technology permits the analyses of samples without making any type of assumption or putting any constraints on even narrow sample size distributions. This patent protected PIDS technology enables an LD instrument to resolve multimodal samples at the size range as small as 81 nm without the need of mode-picking (figure 2, high resolution). It also proves that this PIDS instrument has a better algorithm to provide high resolution results than the first instrument. In essence, it measures what should be measured without the need to make assumptions or extrapolate the results in the submicron range.

Conclusions

For a laser diffraction instrument to measure any sample with prior knowledge or presumption, the important things are to design the instrument correctly so it can measure scattering intensity angular variation sensitively even in the submicron range, utilize a fitting algorithm smartly and thoroughly, and provide users functional software. In a few instances some constraints can be applied in the algorithm, but for most realistic samples applying such constraints will no be applicable. Therefore, the accuracy and resolution output from the performance of an instrument has to be done without any need for fitting mode selection.